Why is PVT the best choice for pressure vessels?

• high quality, reliable product

• stock vessels for fast delivery

• very competitive on price

• comprehensive standard range

• bespoke products available

• excellent customer care

• Any RAL Colour

• Standard PED and ASME X (code stamped if required)

PHOENIX VESSEL TECHNOLOGY LTD

Operational Excellence and First Time Quality

Phoenix prides itself with Quality and Operational Excellence.

Our R&D Design Team provides the best Technical Support along with bespoke pressure vessel Customization. We always meet the most urgent customer time demands.

We have almost 40 years of unrivalled Customer Care & After Sales Assistance.

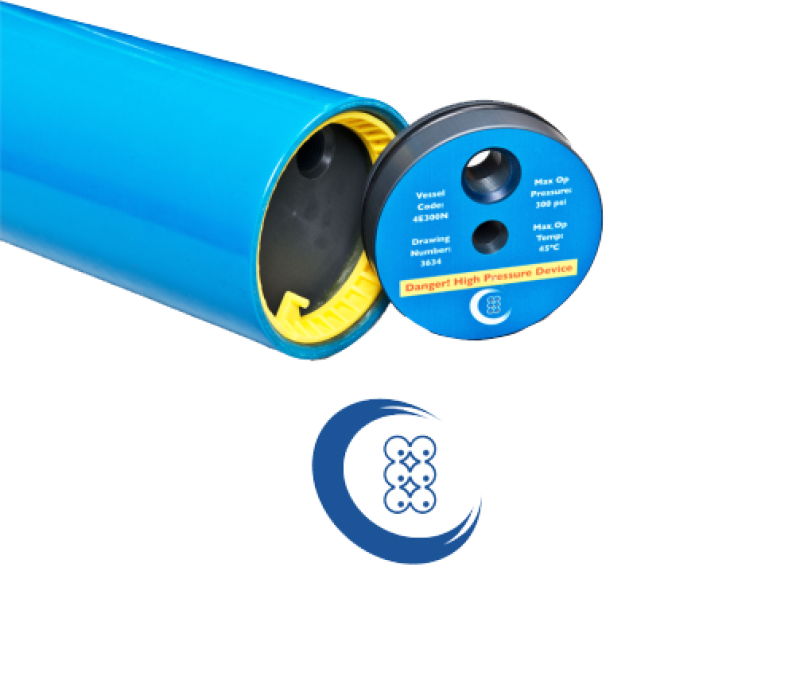

Highest Quality Product Available

Phoenix pressure vessels will expect to last the entire life of the RO system. To ensure this we have selected the best materials and used the newest technology for pressure vessel filament winding. Phoenix our proud to produce the best REVERSE OSMOSIS vessels in today’s global market.

Materials of Construction

When you discuss GRP (Glass Reinforced Plastic) Pressure Vessels, the materials of construction play a critical role.

The materials of construction determine the life of the vessel and well as the corrosion resistance and the quality of the water produced.

Reliability

Phoenix pressure vessels are individually tested before they are packed and shipped for delivery. We pride ourselves with excellence of workmanship, high quality materials and in-house testing. You will always receive high quality leak-free vessels with Phoenix.

ASME Code X

Phoenix designs and produces standard and bespoke vessels to the ASME Code working under the regulatory guidance of the American Society of Mechanical Engineering. This accreditation is respected within International Safety Standard Regulation upon Fiber.

Reinforced Plastic Pressure Elements written specifically for fiber reinforced plastic pressure vessels. Phoenix pressure vessels can be supplied with an ASME Code stamp and a National Board Registration number if required. Phoenix also holds a CRN (Canadian Registration Number).

End port and Side Port

Phoenix provides a diverse range of different types of permeate port connections. The End Port and Side Port lengths can be adjusted to meet your skid design requirements depending on your requirements. We can provide multiple side port configurations in most diameter sizes depending on pressure and element length requirements.

Certification list

- Certificate of Conformity

- Certificate of Origin

- ASME X

- CRN

- ISO 9001

- WRAS

Metal Components

Phoenix only use the best metal components for its pressure vessels. All of our Side Ports are designed & produced from top quality materials to avoid any corrosion related issues. We only use the best supply chain companies providing customer sustainability.

Every port, insert and retaining ring are PMI (Positive Material Identification) checked in-house using an XRF Gun to ensure complete accuracy of metal parts are data logged providing 100% traceability. The PMI checks are essential for ASME requirements along with Major Projects where documentation of material traceability is required. All metal parts are supplied with unique CMP (Component Part Numbers) as standard.

Each part is 100% traceable to the serial number of each vessel.

Plastic Components

Phoenix pressure vessels use Thermoplastic Components as standard for corrosion resistance. They are selected for strength, corrosion resistance, purity and durability in service. They are manufactured & certified to meet ASME and WRAS approval for potable water requirements.

Each part is 100% traceable to the serial number of each vessel.

All plastic component parts are supplied with unique CMP (Component Part Numbers) as standard.

GRP Body

Phoenix pressure vessels are all filament wound using the best glass rovings and custom blended epoxy resins that has been cured at specific temperatures for strength, stability and longevity.

Our range of pressure vessels are 2.5” to 11” in diameter and up to 7.5 elements in length.

Nearly 40 years of manufacturing knowledge and technical experience has provided unrivalled chemical data information providing only the best raw materials are used for our Pressure Vessel Production.

FRP Liners can also be used in our manufacturing production where high chemical resistance is required such as acid mine drainage or very aggressive leachate removal.

Our specifically formulated resins have been selected for long shelf life as well as better performance in tough service environments. All of our raw materials are manufactured & certified to meet ASME requirements and 100% traceability including serial batch number of each vessel.

Special Bespoke Products

Phoenix Pressure Vessels are globally renowned for their expertise within the composite industry for manufacturing Special Bespoke Products for nearly 40 years. We have excelled in every industry sector including Waste Water, Pharmaceutical, Oil & Gas, Petrochemical, Food and Beverage, Marine, Electronics, Landfill and Mineral Extraction, Iron and Steel, Seawater Desalination, Ministry of Defence, Superyachts and Cruise Ships, Textile Printing, Hotels and Leisure, Electroplating, Hospitals and Laboratories, Automotive and Aerospace and of course Drinking Water.

Our vessels are used for Reverse Osmosis, Forward Osmosis, Closed Circuit Reverse Osmosis, Ultrafiltration and Nano Filtration.

If you have any questions or requests, you can simply write to us using the form.

Phoenix Vessel Technology Limited

Unit 2, The Old Bakery, Lower Tuffley Lane,

Gloucester, GL2 5DP, UK

+ 44 (0) 1452 311673

+ 44 (0) 7956 759251